SURFACE DESIGN + PILLOW FABRICATION

Surface design and construction of compostable pillows

OVERVIEW

My role: Art director and designer

Industry: Fashion and interior design

Duration: 6 months

THE CHALLENGE

Creating 5 pillows suitable for indoor/outdoor use that mesh with Elevate Graphic Design’s studio aesthetic.

Elevate Design was looking to have pillows with a custom pattern made for both indoor and outdoor use at their Vancouver studio. They wanted colours that would complement the greenery surrounding the studio patio as well as the colour palette used inside the studio. The current interior space incorporated mainly grays and neutral colours with occasional pops of saturated orange, and furniture and art that evoked a mid-century modern vibe. The client wanted accent pillows that would bring a retro—yet contemporary—pop of colour to both spaces. Further parameters included fabric durable enough for pets, and a turnaround time of three weeks.

THE CLIENT

Elevate Design is a graphic design and illustration studio based in Vancouver, BC, Canada.

MY ROLES + RESPONSIBILITIES

- Creative director

- Designer

- Pattern maker

- Sewer

- Materials sourcer

OUTPUTS

- 5 indoor/outdoor pillows

- 1 surface design

TOOLS I USED

- Adobe Photoshop

- Adobe Illustrator

- Industrial sewing machine

- Hand sewing tools

- Zippers

- Printer and paper

Phase 1: discovery

RESEARCH

In addition to learning more about Elevate Graphic Design’s work and workspace, I explored historical surface design patterns and interior design from the 1930s to mid 1960s. I also researched residential and industrial furniture from this time period. Contemporary surface designer Orla Dermott’s retro-inspired textile designs were also a departure for some of my research.

MATERIALS RESEARCH

I researched a variety of textiles used in interior/exterior design, and, due to the project’s shorter timeline, looked at Canadian companies that supplied and printed these fabrics.

Phase 2: research + define

- I’d identified numerous materials in my discovery phase, and it was time to narrow down options that would be ideal for the project.

- I sourced a reputable and reliable on-demand fabric printer in Montréal. They not only printed on a variety of fabrics, but had quick turnaround times and stocked a selection of sustainable fabrics. The inks and print processes used by the print provider also promoted colour vibrancy and lightfastness—essential for textiles used in an outdoor setting.

- I chose to use OEKO-TEX certified cotton canvas because of its tight weave, durability, clarity of print details, affordability, ease of care, and its lower impact on the environment (it’s compostable).

- I researched different colourway possibilities.

Phase 3: design + ideation

PROTOTYPING + IDEATION

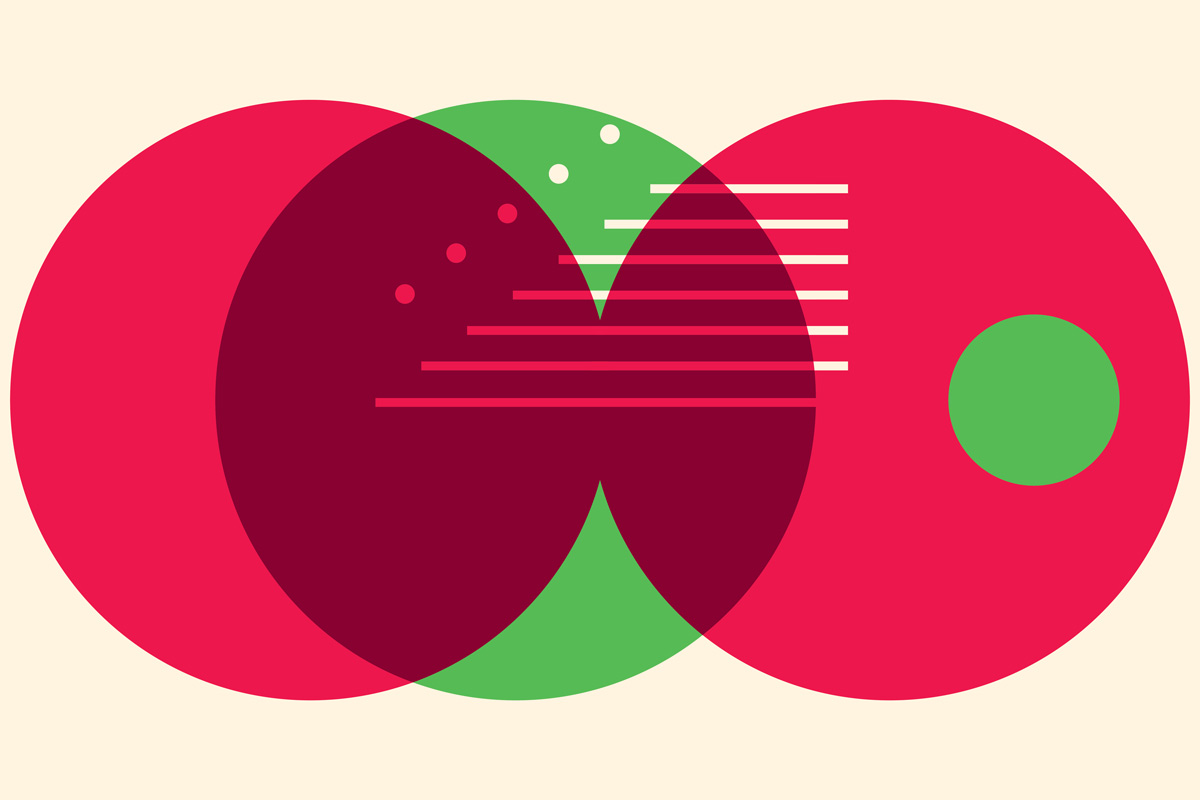

- I created 4 surface design options in Adobe Illustrator and Photoshop, and tested these out on digital pillow mockups, adjusting scale and colours.

- I sourced existing pillow inserts from IKEA, and built the pillow case pattern around these dimensions. This helped allow for speedier prototyping.

- I created 2 paper mockups of the pillowcases to test sizing, and then sewed a mockup pillow with scrap fabric (of a similar thickness and hand).

- I digitised the patterns in Adobe Illustrator, and made minor adjustments.

- I sourced zippers and thread from a local company in Vancouver.

REFINFING + EDITING

- I confirmed the final surface design with the client and uploaded my textile designs to the fabric supplier/printer’s website. I then purchased the OEKO-TEX certified cotton canvas in the quantities I needed.

- Once I received the fabric from the supplier, I washed and dried it to test for shrinkage.

- I constructed one full-sized pillow with the washed fabric to test my pattern design, the fabric, thread, and fastenings.

Results

- 5 durable, pet-friendly and vibrant indoor/outdoor pillow cases with inserts.

FUTURE CONSIDERATIONS

The durable nature of the final fabric was much easier to manage with an industrial sewing machine. I’d started sewing the fabric with a home sewing machine, and it just wasn’t powerful enough.

WHAT WAS LEARNED?

I learned how colour-accurate direct-to-garment printing can be, especially with the right fabric. I was pleasantly surprised at how vibrant and durable the final print was.